Recap of an Interview with David Lewandowski, Azenta Life Sciences, and Carol Houts, Chief Strategy Officer at Germfree, in partnership with Phacilitate

The cutting-edge domain of cell and gene therapies is undergoing a remarkable transformation, with innovative technologies and groundbreaking treatments promising to revolutionize healthcare. However, as these therapies continue to advance, so do the challenges surrounding patient access, compressed timelines, and regulatory dynamics.

A recent interview with David Lewandowski, Director of Business Development for Automated Storage at Azenta Life Sciences, in cooperation with Germfree and Phacilitate, discussed insights into the intricate web of issues in this field and how automated sample storage solutions, including automated cryostorage, are playing a pivotal role in supporting the industry.

Here’s a summary of some of the issues from that discussion.

The shifting manufacturing paradigm

Traditionally, pharmaceutical manufacturing followed a centralized model with a focus on quality control and standardization. However, the landscape is evolving with the emergence of distributed and point-of-care manufacturing models. These models enable therapies to be manufactured closer to the patient, improving accessibility, and potentially reducing costs. But this shift introduces new challenges in managing logistics, maintaining product quality, and ensuring adherence to cold chain requirements.

The crucial role of cold chain and cryostorage

Cold chain management becomes paramount when dealing with cell and gene therapies. Unlike many traditional pharmaceuticals, these therapies often require stringent temperature controls throughout their journey — from starting materials to the final product. Lewandowski pointed out that while pharmacies have experience with products that can be stored at warmer temperatures, the complexities of cell and gene therapies demand a deeper understanding of cryopreservation.

Moreover, the need for transparency and data management in cold chain logistics is crucial. The integrity of these therapies relies on maintaining specific conditions during transportation and storage. Lewandowski highlighted the potential of automation and digital solutions to ensure consistent cold chain compliance, as well as to track and record the journey of these valuable products.

Data transparency and inventory management

As the volume of samples and materials increases, the challenge of tracking, managing, and documenting these resources becomes more complex. Lewandowski’s background with the International Society for Biobanking underscores the difficulty of managing vast quantities of samples while adhering to best practices. He stressed the importance of automation in inventory management and data transparency. Advanced software solutions are emerging that aggregate data and enable virtual management of inventory across various locations, enhancing efficiency and accuracy.

Scaling up for success

While clinical trials in cell and gene therapy often involve relatively small patient populations, the approval of a therapy brings the challenge of scalability into focus. Lewandowski noted that the transition from a successful trial to large-scale production requires meticulous planning and preparation. The availability of automated solutions for inventory management and sample handling will enable a smooth transition from clinical trials to widespread distribution.

Globalization and regional hubs

The global nature of the biopharmaceutical industry requires solutions that accommodate international distribution. Lewandowski highlighted the potential for regional hubs that serve as manufacturing and distribution centers. This concept envisions central hubs of expertise that can effectively supply therapies to remote locations. As cell and gene therapies become more accessible, patients could benefit from treatments without the burden of extensive travel.

Envisioning the future

Looking ahead, Lewandowski’s vision of the future entails a combination of regional hubs, advanced automation, and agile manufacturing. He envisions a scenario where therapies are manufactured at central hubs and distributed efficiently to various regional centers. These centers could then serve as distribution points to reach patients in even the most remote areas.

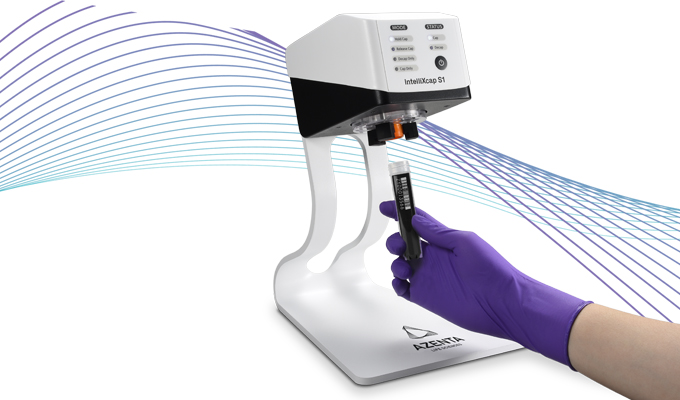

In this landscape, the role of companies like Azenta Life Sciences becomes essential. By providing specialized services in automated sample storage, cryostorage, and inventory management, Azenta contributes to streamlining the manufacturing and distribution of cell and gene therapies. The expertise Azenta brings to the table helps biopharmaceutical companies navigate the challenges of the industry and ensures that patients receive these life-changing treatments in a timely and efficient manner.

Listen to the full interview

Conclusion

The world of cell and gene therapies is complex, with challenges spanning manufacturing, logistics, and regulatory compliance. The move towards distributed manufacturing and point-of-care models necessitates innovative solutions for maintaining product quality, managing inventory, and ensuring cold chain compliance. Automated sample storage solutions, coupled with advanced software and cryostorage capabilities, are emerging as critical components in supporting this industry’s growth.

One example of this is the CryoArc™ Pico , a smaller scale automated cryostorage solution that fits spaces from lab to clinic. The CryoArc Pico supports companies with cell and gene therapies that are in clinical trials and brings therapeutic materials closer to the point of use.

As the field continues to evolve, the collaboration between biopharmaceutical companies, research institutions, and companies like Azenta Life Sciences will play a pivotal role in shaping the future of patient access to transformative cell and gene therapies. With a focus on scalability, automation, and data transparency, the industry is poised to overcome challenges and bring these groundbreaking treatments to patients worldwide.

About the Guest

David Lewandowski

David Lewandowski helps lead market conversations around scalable cold chain distribution models for advanced cell therapy and tissue distribution.

As a leader at Azenta Life Sciences, he serves as an industry conduit representing the Azenta portfolio including outsourced GMP storage, automated cold chain solutions, and multiomics. Leveraging more than 20 years of experience in cold chain and distribution-related topics in biotech, he assists organizations in planning their scale-up and distribution strategies.

Outside of his work at Azenta, he serves in leadership roles on the ARMI BioFab’s Leadership Advisory Council and the International Society for Cell Therapy Cold Chain Working Group. He also remains involved in the International Society for Biological and Environmental Repositories (ISBER), where he served as the President in 2019.