What’s behind the eco-friendly cold-air technology used to power the Azenta BioArc Ultra High Density -80°C Automated Sample Storage System?

The next generation high-density storage automation system by Azenta Life Sciences, the global leader in sample storage automation, was supported by MIRAI Intex, a leading provider of innovative refrigeration technology; and Refolution GmbH, a German engineering firm specializing in sustainable cooling technology integrations.

Incorporating Recirculated Air as a Refrigerant

The use of MIRAI Intex’s air cycle refrigeration units in the Azenta BioArc system underlines a commitment to reducing the environmental impact of ultra-low temperature freezers used for sample storage and biobanking. Using recirculated air to create a cooling effect, this proven technology not only reduces energy consumption but also eliminates the need for potentially harmful chemical refrigerants, aligning with global efforts to promote sustainability in scientific research, biobanking, and healthcare.

The MIRAI air cycle technology delivers environmental advantages, including using less power and having zero carbon emissions, along with the ability to maintain consistent temperatures, critical for the preservation of sensitive biological samples.

How Cold Air Refrigeration Works

The BioArc Ultra open-cycle refrigeration technology developed by MIRAI Intex, and adapted for the Ultra by Azenta with engineering support from Refolution, provides sustainable refrigeration.

The MIRAI technology has proven to be highly reliable. With over 200 million installed machines since 2018, the MIRAI refrigeration system has logged an estimated 3.5 million working hours without needing a single compressor replacement.

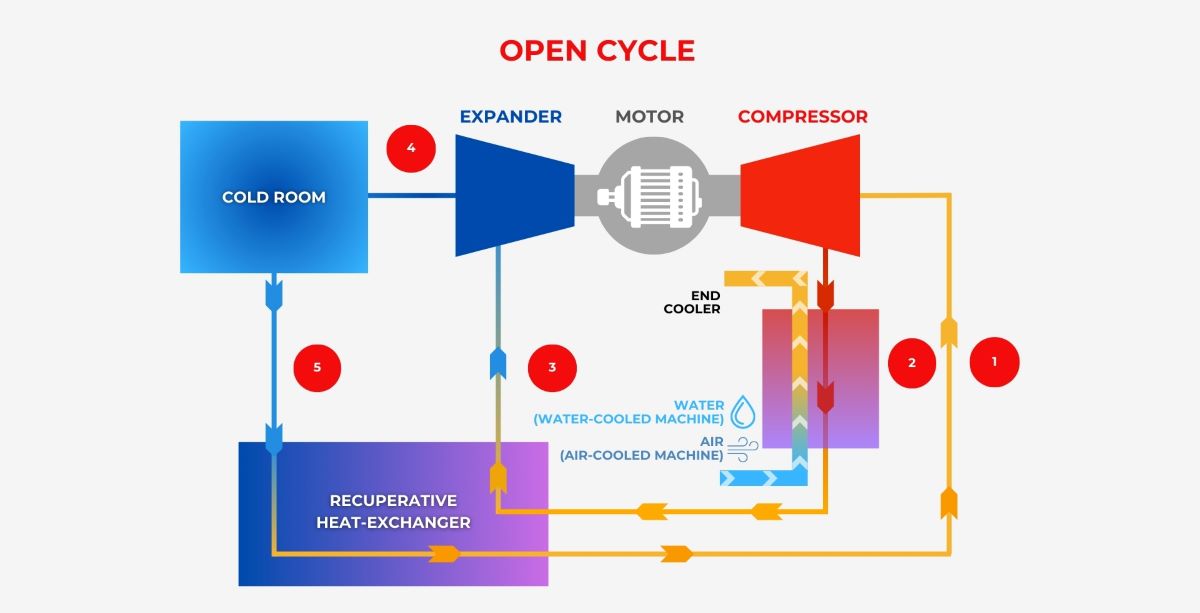

The system uses an open-cycle process in which air is heated during compression and cooled through a series of heat exchangers and then expanded to reach ultra-low temperatures. By repeating the cycle of compression, cooling, and expansion, it’s possible to achieve temperatures down to -160°C. The system is able to maintain temperature accuracy within 0.5°C, based on internal tests provided by MIRAI Intex.

Air is supplied directly to the cold room, eliminating the need for indoor evaporators and auxiliary fans. This operates at low pressure, and with natural air as refrigerant, making it a safer option compared to alternatives maintaining temperatures from -40°C to -110°C.

Snow-catcher Prevents Moisture

In ultra-low temperatures, moisture freezes instantly. To combat this, the BioArc Ultra uses a snow catcher – a Humidity Extraction Device (HED) – that eliminates the need for frequent defrosting. This device enables the BioArc Ultra to operate continuously, saving cooling power and extra energy typically consumed during defrosting.

Many Advantages of Using Air Instead of Refrigerants

Since the system uses air instead of other chemicals, this eliminates the need to replenish refrigerants or to do refrigerant testing. This means less time spent on maintenance and lower running costs. It also makes the system more eco-friendly, as it doesn’t create ozone-depleting substances.

Furthermore, all manufacturing processes at MIRAI Intex, including the production of the refrigeration system, adhere strictly to the ISO 9001:2015 certification. It is a safe solution free from chemically active substances, fire, or explosion risks.

Leveraging Global Expertise in Sustainability Engineering

The integration of sustainability-focused engineering, space efficiency, and air refrigeration technology has created the next generation automated sample storage system for the life sciences, biobanking, and healthcare research industries.