The ever-expanding horizon of medical research and healthcare delivery owes a significant debt to the technological advancements that have shaped the industry. Among the many innovations, cryopreservation stands out as a pivotal technique that preserves the integrity and functionality of biological specimens over extended periods. By freezing cells, tissues, and even whole organs at sub-zero temperatures, cryopreservation has become a cornerstone of modern medicine, impacting everything from cancer therapy to reproductive medicine.

Adapted from “Cell Therapies on Ice: Seven Trends in Cryopreservation To Enable Cell and Gene Therapy Research” by Erica Waller published in Technology Networks, this article delves into the latest trends in cryopreservation, highlighting seven pivotal developments that are refining the practice, and defining its crucial role in advancing medical research and treatment.

1. Keep up with clinical evolution

The landscape is evolving towards enhanced clinical access, necessitating tailored solutions for clinical trials. As research labs manage clinical trials through each phase, more and more people are involved, which is why scalability should be an important consideration from day one. As the number of samples increases, so does the complexity of carefully handling cryopreserved samples, as well as managing and tracking them. For example, if a patient decides to withdraw from a trial, the researcher needs to know how to access their individual sample and remove it, without jeopardizing the other cryopreserved samples.

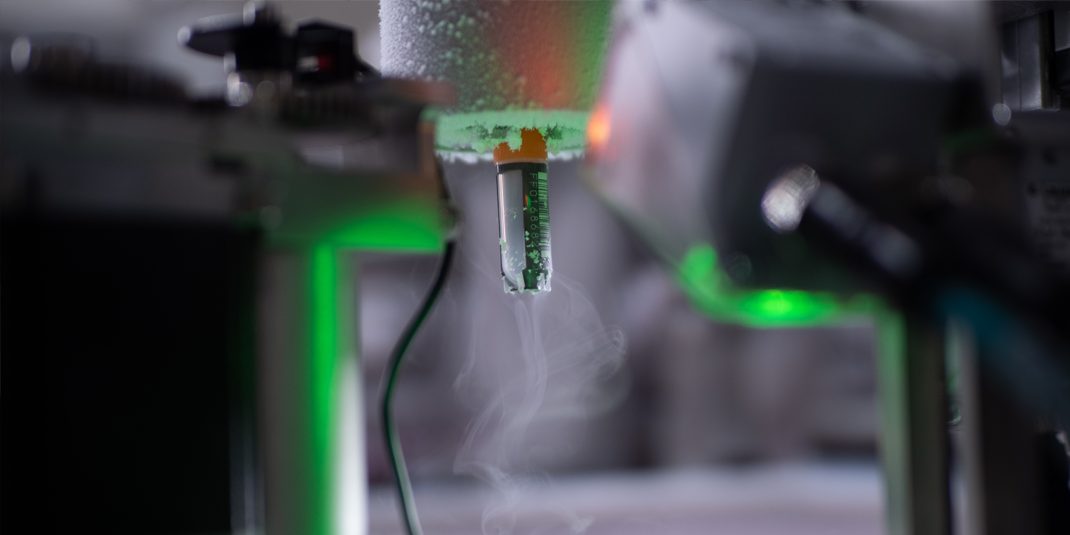

2. Leverage automation advancements

Automation in cryopreservation eliminates the human error factor. It is becoming pivotal in streamlining cryostorage processes, bolstering efficiency and ensuring sample integrity. An automated system handles sample management and supports compliance – it knows where each sample is and delivers it, without the manual process of digging through freezers. This helps keep lab workers safe by keeping them out of the liquid nitrogen tanks, along with ensuring the safety of the samples they manage. As a lab scales from 100 samples in storage to a million, automation makes it much easier for researchers to find what they need. Organizations are increasingly opting for hybrid methods of cryopreservation storage (manual and automated) as well as hybrid locations of storage (onsite and offsite, internally and externally managed, etc.) depending on the level of research activity and value of the samples. Read more about the Role of Automated Sample Storage in Cell & Gene Therapy.

3. Manage cold chain complexity

During the pandemic, everyday consumers became well-versed in supply chain complexities. Similarly, the cold chain presents challenges where cryopreservation processes can break down. The cold chain encompasses everything that happens to a sample from the moment it’s frozen down, through the storage process, until the moment it’s thawed and administered to a person or used in a research process. This includes any transit between sites, which can be difficult to account for when third-party logistics carriers like UPS or FedEx take custody of the sample. Effectively managing the cold chain warrants meticulous oversight and tracking of temperature data for end-to-end traceability.

4. Increase sample viability with precision tracking

Innovative tracking mechanisms are crucial to monitor access and exposure, ensuring sample viability and supporting regulatory compliance. When the stakes are curing cancer or other life-altering diseases, there’s no room for error. If a cryopreserved cell is damaged, that therapy won’t be as effective for the patient. Additionally, with the costs of CAR T therapies upwards of half a million dollars or more, precision tracking and higher sample viability can help boost the efficiency of the entire process and lower costs per viable sample. Manufacturers of these therapies are demanding tracking and traceability to show precisely where the sample is, the temperature it is being held at, and the history of what has happened with each sample. Automation in the cryopreservation process also delivers increased security with administrative-defined user level controls and access. Read more about Protecting Cell Viability During Cryopreservation.

5. Minimize cell damage caused by transient warming

Transient warming can happen any time a sample comes out of the cryogenic freezer, and this can reduce cell recovery. When freezer doors are opened and materials are removed, both target samples and non-target (innocent) samples experience warming. However, when robotics are used to automatically locate and select samples within the cold storage unit, it creates a much more controlled environment for retrieval. A deeper understanding of the real effects caused by transient warming is imperative to minimize cellular damage and ensure effective treatments. Read Expert Insights on Cryopreservation & Transient Warming from Dr. Jason Acker.

6. Ensure quality and compliance through data governance

Robust data management strategies are essential for quality and compliance. Along with the good manufacturing practice (GMP) compliance process, the FDA’s 21 CFR part 11 regulation ensures the integrity and security of electronic records and signatures as electronic documentation usage increases in clinical trials. Organizations regulated by the FDA must ensure processes are compliant, including audit trails for temperature monitoring with electronic time-stamps and date-stamps to demonstrate proper data governance and compliance.

7. Champion evolving standards

The establishment of industry standards for storage, materials and processes is central to success. Standards for cryopreservation are still evolving and that’s a big hurdle for further innovation. Clearly defined standards for microplates, for example, allow scientists to work with automated laboratory instrumentation across different labs and different equipment manufacturers. The SBS standard exists for cold storage at -20 and -80 degrees Celsius, but a similar standard does not exist for labware used at cryogenic temperatures. There is currently an industry-wide effort to create cell therapy cryopreservation standards and best practices, which was kicked off at the 2022 Cryogenic Considerations for Cell & Gene Therapy Symposium. Once these standards are in place, it will simplify and speed the work of cryobiologists to let them bring lifesaving therapies to market faster. Learn more about Addressing Standardization Obstacles in Cryostorage.

The future of cell and gene therapies includes cryopreservation

Understanding the intricacies of cryopreservation and keeping up with the latest trends is crucial for any organization involved in cell therapy and related medical fields. While cryopreservation has long been a fundamental aspect of medical science, its role is becoming increasingly significant as we push the boundaries of what’s possible in cell and gene therapy, organ transplantation, and beyond.

As we look to the future, it’s clear that the role of cryopreservation will only grow in importance. Forward-thinking organizations are already investigating how innovations in cryo-technology can augment their research and clinical applications to enhance productivity and success. The next decade promises to be one of exciting progress, as these cryopreservation trends help fuel medical breakthroughs and improve patient outcomes.

To stay updated on the evolving world of cryopreservation and learn more about current issues and trends in cryopreservation, register for updates and to download content from the Azenta Cryo Symposium. By keeping pace with these trends, researchers and clinicians can ensure that the full potential of their work is realized, ultimately leading to better healthcare solutions for all.

Discover the latest development in cryostorage automation for high-value samples and therapy materials that fits any space from lab to clinic.

This article was originally published in Technology Networks. Republished with permission.

About the Author

Erica Waller

Erica Waller is a senior product manager for cryo automation and stores at Azenta Life Sciences, headquartered in Burlington, MA, USA. She holds a BS in Mechanical Engineering from MIT and was a systems engineer for Brooks Automation (now Azenta Life Sciences) for several years prior to her current role. Today, she oversees the cryo storage and automation portfolio for Azenta Life Sciences.